The rear suspensions on most modern motorcycles employ a linkage to make shock movement progressive. In other words, as the swingarm moves through its arc, leverage afforded by the linkage transfers that movement at an accelerating rate to the shock.

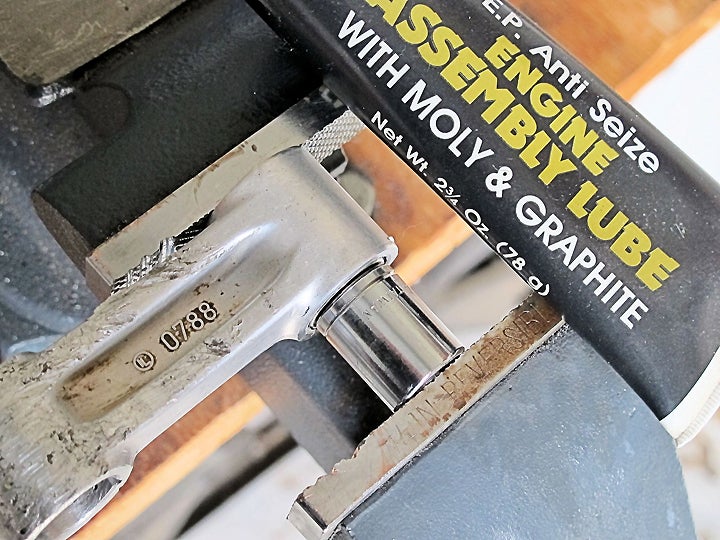

The goal is to provide relatively light and supple damping at the beginning of suspension travel and firmer resistance to bottoming at the deepest extreme. This is the best of both worlds. The rear wheel is allowed to rise easily to hug the contours of small surface irregularities, maximizing traction and ride plushness. But it can’t just blow through the shock’s full stroke in response to larger impacts, such as square-edged bumps or potholes on the road, or landings off big jumps on a supercross track.

Except in rare instances (air shocks are pretty rare these days), your shock will contain oil. Liquids are non-compressible. Think of your shock as two chambers connected by a set of orifices. During compression, oil is forced from one chamber to another, with the orifices limiting the speed of this transition. The faster the shock is compressed, the harder it is for the oil molecules to crowd through those orifices–picture Black Friday shoppers struggling to squeeze through a store entrance that would normally present little resistance to lighter traffic. A linkage produces this same effect as the shock approaches its bottoming point. It rushes and “crowds” the oil at an increasing rate as travel is used up, thereby maintaining an ever-firmer cushion to slow down suspension movement, rather than transmitting a sudden jolt at travel’s end. Linkages can be designed to deliver a steeper or shallower progression rate to suite their intended use.

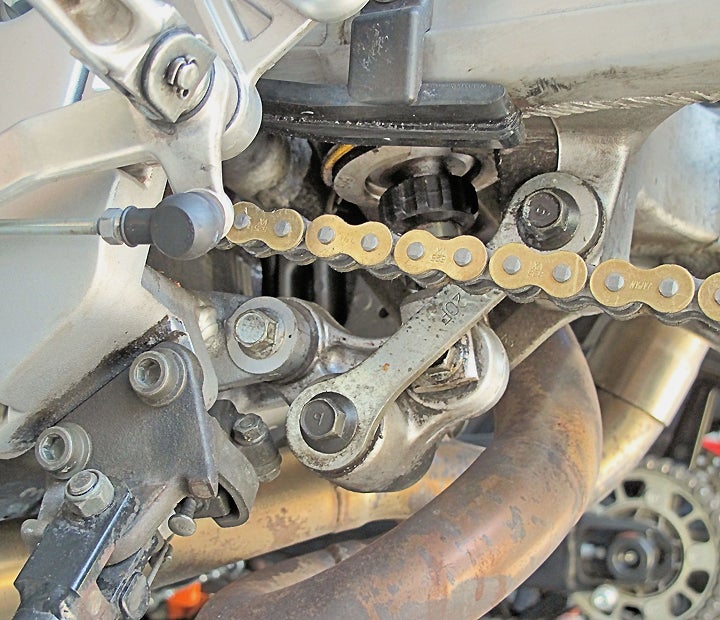

Some rear suspensions try to address the need for progressive damping by other means. Instead of a linkage, they utilize valving in the shock that allows oil to flow more freely at full extension, and less freely at full compression. You’ll probably never read a magazine article that equates this solution to a linkage setup; at best, they perform well “for a non-linkage system.” One such example is KTM’s enduro lineup. Fans of these bikes value the ease of shock R&R (literally a two-bolt, three-minute affair), the lack of linkage maintenance, the reduced vulnerability to damage, and the lower equipment cost. Also, unlike motocrossers, these riders don’t need their suspensions to cope with hard landings from high-altitude; the limitations of progressive damping shocks are less problematic without the demands of aerial acrobatics.

Linkages contain bushings and bearings to manage friction at their joints. Because they’re almost always located near the shock’s lower end, usually hanging down below the swingarm, they’re regularly exposed to lots of abuse. Off-road bikes often subject their undersides to impact, and all motorcycles pelt this area with dust, water and gritty crud. Of course, even if they were completely shielded from such threats, the friction-bearing surfaces would wear from use alone.

Linkages Need Love, Too!

Unfortunately, linkages are often neglected, even by otherwise conscientious owners. They’re not highly visible, wear and tear is totally invisible, and they can be awkward to access. Special tools are listed in shop manuals for bearing removal and installation, and these are invariably quite expensive (keep reading for a super-cheap alternative). Also, the bike must be supported in such a way that the rear is completely unweighted, which can be a challenge on some street bikes.

Still, none of these factors make linkages any less needy or worthy of attention. To check the condition of yours, first suspend the swingarm and rear wheel. If you have a centerstand that naturally lifts the rear wheel off the ground, this part is a cinch. If your centerstand tends to lift the front, you can have an assistant push down on the bars for this part to get the rear end up. Barring either of those possibilities, you’ll have to lift the bike by its frame. This is accomplished easily for off-road machines by hoisting them onto a stand that supports them from underneath their motors, with their frame rails bearing the weight. Some street bikes can be raised off the ground in this same way. When this isn’t possible, there’s another method available to the home mechanic without a hoist.

Use a workstand to lift the rear of the motorcycle off the ground. This is only a means to an end; it won’t work for rear suspension maintenance because it doesn’t remove any load from the swingarm. Now, get two tall jackstands ready near a sturdy place in the frame where you can slide a stout pipe through. The idea is to have the bike’s weight supported by this pipe on the jackstands, once the workstand is removed. Of course, the area of the frame used must be strong enough to bear the bike’s weight, and should be free of finished surfaces that could get scuffed (place towels between the pipe and the frame in any event). This sounds more challenging than it really is on many bikes, though some will be tricky. Consider the juncture of the rear sub-frame and the passenger peg supports. Although it might require the removal of some plastic, you can probably slip the pipe straight through above the wheel here, and the bike will rest securely on it with little risk of tipping or front-to-back movement.

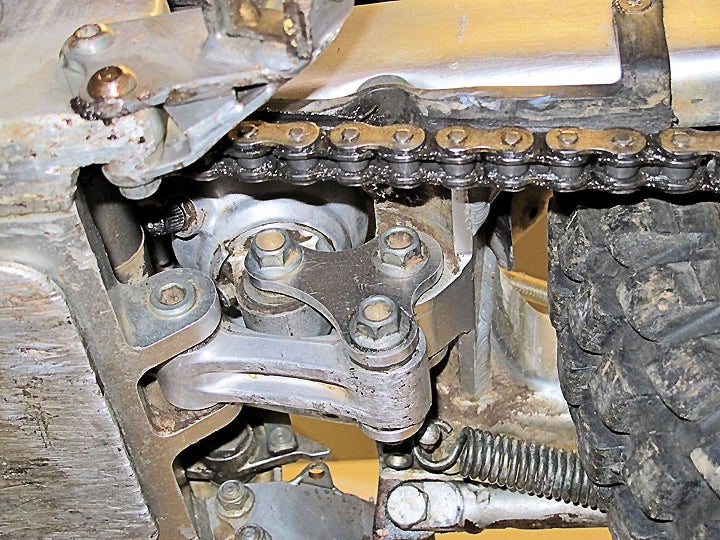

With the rear suspension unloaded, grasp the ends of the swingarm and try to wiggle them. Check for side-to-side movement, which likely indicates worn swingarm bearings/bushings. Then check for vertical free-play – between where the swingarm comes to rest and where the suspension’s resistance is first encountered. While this can also result from swingarm component wear, it’s most likely the result of worn linkage parts (especially in the absence of lateral movement). Don’t make this assessment by tugging at the wheel; slop detected there could be a wheel bearing issue. Still, while it’s convenient, check your wheel bearings, too.

An important note: If you do detect problems with the wheel bearings or swingarm pivots, these warrant your immediate attention. Both will detract from suspension performance, and a full-blown failure of either could result in loss of control while riding. On many bikes, lubricating or replacing swingarm bearings is the same in principal as those operations on linkage bearings, although disassembly is obviously more involved. We won’t cover it here, though, because swingarm removal can be so different on different motorcycles. Review the procedure in your service manual, and see if you’re up to it.

Even if you detect no slack in the system, linkage bearings still require regular cleaning and lubrication. A few models come with fittings to allow the use of a grease gun without disassembly; unfortunately, the vast majority do not. Consult your owner’s manual for a schedule of chassis lubrication, but keep in mind that riding in wet/dusty/harsh conditions is apt to shorten the service life of bearing lubricants–and subsequently, the bearings themselves. Also, it’s not uncommon to find that a brand new motorcycle may have been assembled with precious little grease in these (and other) load-bearing components. The good news is that getting your bike’s rear end off the ground may be the hardest part of this process, depending on your linkage’s design.

Our sample bike actually had only a small amount of tell-tale swingarm free play. However, its linkage bearings were in much worse condition than that assessment suggested. All had a gritty, notchy feel when turned by hand, and two were very hard to turn at all. They were packed with dense sludge, as though mud had been substituted for grease. It was a wonder the rear suspension moved at all! But so much weight and leverage are involved, and so little rotation is actually required at each individual pivot, that movement was preserved–just not smooth, supple movement. Action out back was much improved with new, well-lubricated bearings.

To do any actual service, you’ll need to not only support the bike’s frame, but also the rear wheel/swingarm. Off the ground, those parts weigh on the linkage and try to extend the shock, making bolt extraction difficult and even more awkward than it already is due to location. The rear end will also fall to the ground when you remove something. So, prop up the rear wheel slightly to neutralize this reverse tension before beginning any disassembly.

Getting Into It

First of all, get the necessary supplies ready before you begin, as your bike will be disabled for the duration of this project. A shop manual, torque wrench, chassis grease, all the appropriate socket and wrench sizes, and new parts (if indicated by rear end wiggle room) should be handy – along with a bearing removal/installation tool if you’re going to replace worn components. Such tools can cost hundreds of dollars, which may be worthwhile if you’re a tool connoisseur with some money to burn; no doubt they’re more elegant and probably a tad easier to use than what we’re about to offer as a low-cost alternative. But, if you’d prefer to spend less than 10 bucks on something you’ll rarely use, all it takes is a quick trip to your local hardware store.

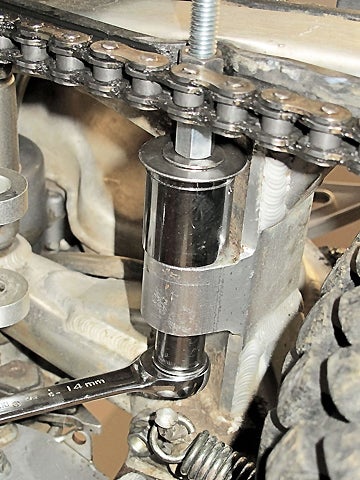

Special bearing tools use the mechanic leverage of a screw to apply concentrated force against press-fit parts. Said leverage can be obtained with a simple piece of all-thread and a few nuts and washers, along with some sockets borrowed from your tool box. Basically, you’ll run the all-thread through the bearing, the part housing it, and a couple of sockets. The sockets will be squeezed against the bearing on one side, and the host part on the other side, using nuts on the all-thread.

On the bearing side, the socket’s outer diameter will be slightly smaller than the bearing’s outer diameter, thus allowing it to press the bearing through the bore and out the other side. The other socket’s internal diameter will be large enough to allow the exiting bearing free egress, but small enough to maintain level contact with the linkage piece or swingarm/frame boss. It’s just a matter of lining everything up and turning the nut on either side; a pair of nuts forced together (like any lock-nut arrangement) will provide purchase for a wrench to hold the all-thread still against the turning of the nut on the opposite side. Washers spread the load evenly and keep the nuts from getting caught in the sockets’ recesses. Choose all-thread that is as large/strong as possible, but that will still fit through the holes in your sockets. The all-thread can be cut to an appropriate length with a hacksaw.

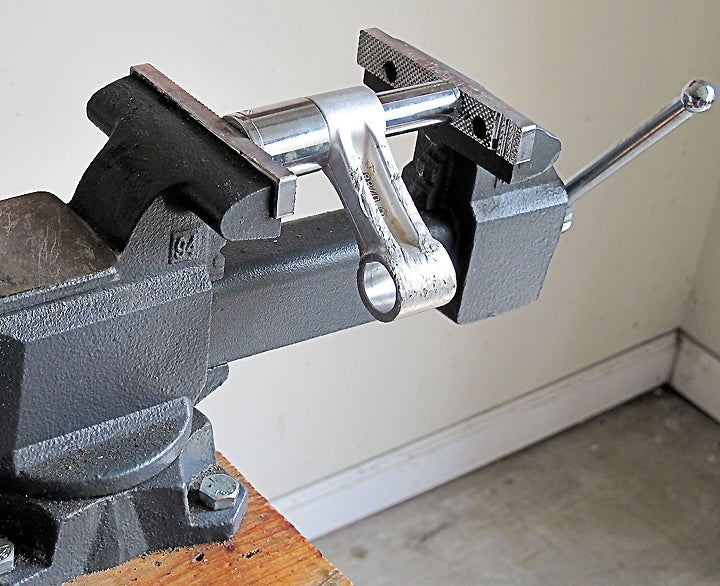

Actually, this very same process can be carried out with a table vice in many cases. Obviously, this won’t work on a frame boss underneath the motorcycle. But for linkage parts that are removed from the bike, it’s even easier than using all-thread. However, during installation, it may also be easier with a vice to apply great force with the bearing slightly cocked in its bore, which will ruin the bearing and damage the bore, which is likely soft aluminum. In any case, proceed slowly and carefully. While substantial pressure is required, you shouldn’t have to apply Herculean force if everything is lined up properly.

Also, there are several ways to ease both insertion and extraction. First, recall that hot metals expand, while cold metals contract. Getting bearings in and out is easier when there’s a temperature differential between the parts. Use a heat gun, propane torch, or even just a bath of hot water (seal the part in a plastic bag and immerse it in a pot of boiling water) to heat the piece a bearing is to enter, and leave the bearings in a plastic bag in your freezer for a few hours. Then, smear the bearing outer surface with a lubricant before pressing it into place. Likewise, heating the outer surface of the part housing the bearing prior to extraction will create a (smaller) heat differential between them. Not only does this reduce the press-fit tension, but it may also break the grip of rust and corrosion at a microscopic level, as the surfaces pull away from each other.

Speaking of rust and corrosion, you may need to apply some penetrating oil to the edges of bearings that refuse to come out. If stronger persuasion is necessary, you can cut the bearing race with a silicone-carbide Dremel bit. Just a small cut will probably suffice once pressure is reapplied. Be careful not to dig into the bore, although a little of this is likely to be unavoidable (and will be of no real consequence, as long as there are no raised surfaces). Once such a bearing is out, use fine grit sandpaper or Scotchbrite to remove corrosion remnants from the bore.

Do not try to hammer bearings into or out of place with a punch! this will damage the bearing’s race and cock the bearing in its bore. Also, a slip will gouge the bore. The resulting trench will not cause problems, but the metal berm raised around it will. New bearings pressed into such a defaced bore will be squeezed out of round by the raised surface, rendering them useless. If you have trouble slipping a bushing into a newly installed bearing, the bearing may well have been deformed by such a surface irregularity.

We found out the hard way on our project bike that someone who’d serviced the linkage previously had done quite a bit of damage to the bore in the swingarm boss; there were several big gouges on one side. This boss is in an extremely awkward location, which is probably what prompted the person to abandon good technique. It also made visual inspection difficult, and we didn’t spot the problem before ruining a replacement bearing. We had to pull the new bearing back out and smooth the bore’s surface with a grinding tool and sandpaper. Although the bore’s condition is still less than ideal, it no longer interferes with bearing function (a snug fit with no race deformation), and this fix was much cheaper than buying a new swingarm!

The earlier bearing’s movement was certainly far from smooth, but it did rotate, even with its race deformed, because some of its needle bearings were pulverized. The first new bearing we installed naively wouldn’t even admit a bushing. We can only assume that the prior replacement involved hammering the then-new bushing into place. Yikes! So, always carefully feel the bore’s interior, especially if you can’t see directly into it, and ensure there are no protrusions.

In many cases, it may be possible to safely hammer a bearing out of its bore using a socket and its extension. Although a bearing can, at least theoretically, also be installed via this same method, the risk of getting it cocked in the bore is high. We recommend using a screw-action tool over a hammer and socket, especially for installation.

If a rebuild is in order, OEM parts must be ordered individually, including bearings, bushings and seals. Aftermarket parts, on the other hand, are usually sold in kits that include all the necessary items. These are often less expensive than OEM parts, and in some cases may offer superior performance and durability. For our example, we chose All-Balls brand, as they have an excellent reputation, but we can’t say whether our kit’s components are actually better than their OEM counterparts. Another respected name is Pivot Works. When installing new bearings, note that one side will be flat, with a square shoulder and numbers etched into it, while the other side will have a rounded shoulder. The latter goes in first; the numbers should face outward.

If your bearings don’t require replacement, then you’ll just be cleaning and relubricating what’s already there. Be aware, though, that seals can wear out before the bearings they protect. If a seal doesn’t pop out easily, or if it shows signs of wear (e.g. cracked or ragged lips), it should be replaced with a fresh one. These are so cheap that you should just get a new set ready before disassembly. Note that these seals go in with their lips facing outward and their flat backs against the bearing races.

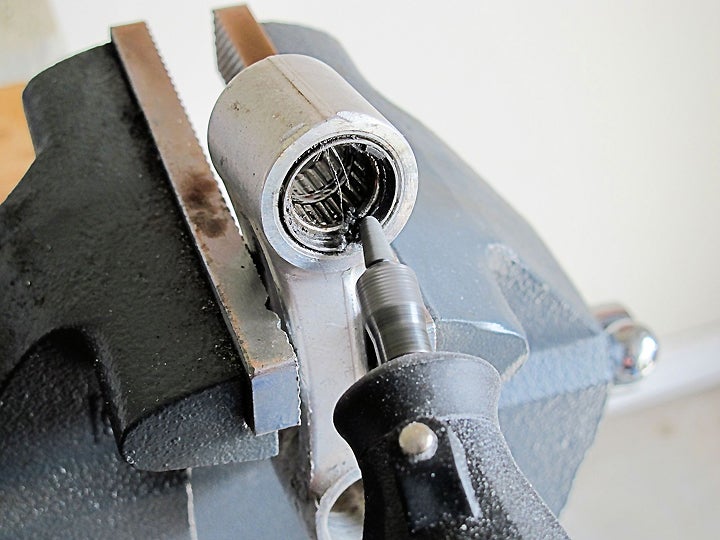

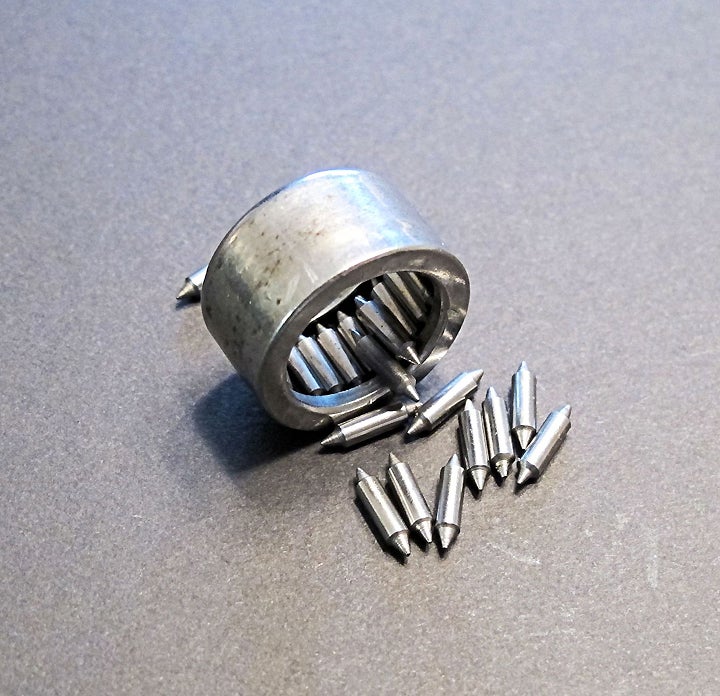

With the linkage pieces removed from the bike and the seals popped out, spray contact cleaner into the bores and bearings to wash out the old grease and accumulated grit. A towel passed through and rotated within each bearing may help. Bearings may be of the “caged” or “uncaged” variety. Caged bearings hold their needles in place behind a perforated plate. An uncaged bearing’s needles are only held in place at their very tips by a small lip around the race’s edge. If a needle gets cocked, its tips will no longer be retained and it will fall out, making it easier for others to do the same.

So, when cleaning an uncaged bearing, keep in mind that the old grease may play a large part in holding the needles in place; when you rinse it away, the needles will be more likely to get loose. This isn’t a big deal, as long as you’re ready to catch any escapees. Actually, with the needles out, the race will be much easier to clean thoroughly. But it is quite a tedious process to replace them. Get into a meditative state, smear a little grease in the empty race, and use tweezers to install the needles, one by one. If you’re careful (and lucky), they’ll tolerate gentle cleaning without evacuating.

Smear or brush fresh grease onto the new or cleaned bearings. Most of this will get pushed out by the bushing, so there’s no need to go overboard. Insert the seals, and fill the space between their lips with grease; this not only provides lubrication, but it also presents an additional barrier to moisture and debris seeking entry. Install the bushings, and wipe off the excess grease to avoid creating a dirt trap.

While you’ve got the linkage off, shock removal will require pulling just one more bolt: the shock’s top mount. Do this now, while it’s convenient, and clean/lube the shock’s bearings. Some linkage bearing kits will include a replacement for the lower shock bearing; note that its removal may require different procedures or tools, so check your owner’s manual for details. Of course, if you discover that a shock bearing is in bad shape, replace it.

Your suspension is now ready for reassembly. Consult your shop manual for the proper sequence, as doing things out of order may leave you without access to a bolt or nut hidden behind a part that you should have waited to install. Double-check all torques; this is not a part of the motorcycle you want to come apart – or bind – during operation! With everything buttoned up, your rear suspension should be silky smooth and subtly responsive.

Your Privacy Choices

Your Privacy Choices